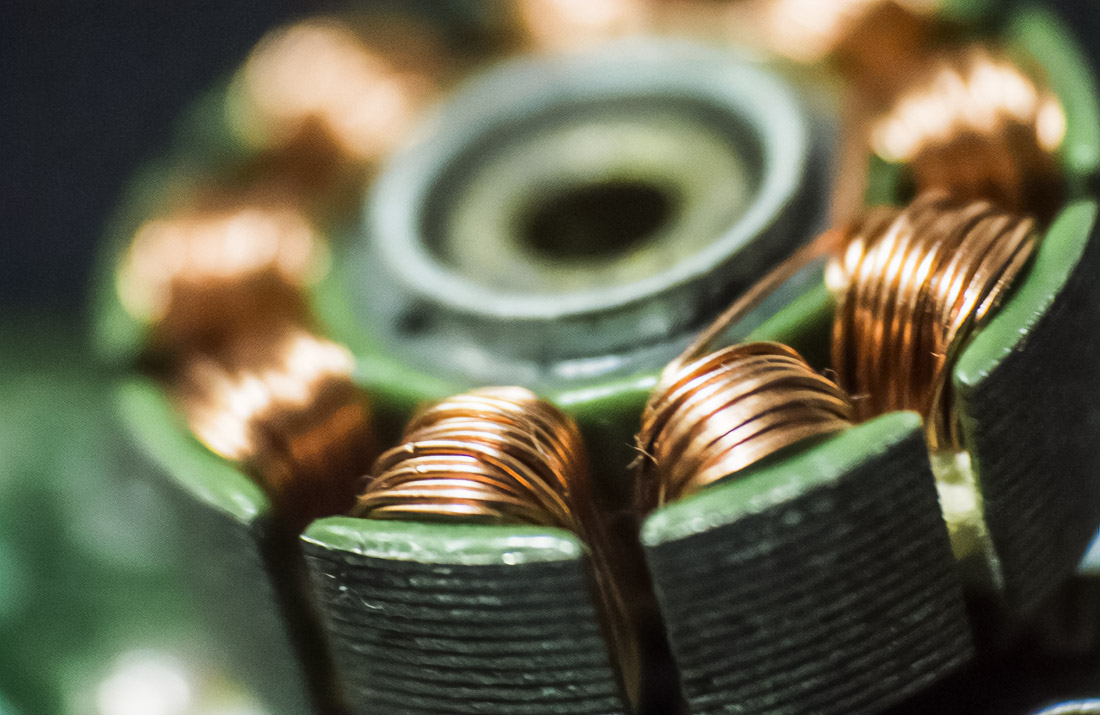

Working with electric machines is rarely predictable. Even if the armature windings and pole coils show a resistance of about 2000 Mohm after rewinding, and the switchboard is carefully polished and tested, sparking suddenly appears. At idle, the engine turns smoothly, runs quietly, no vibrations. It is only necessary to connect the load, and the brushes begin to emit sparks, leaving traces on the surface of the collector plates. The reasons lie not in one detail, but in their interaction.

Brushes, Switchboard and Spark

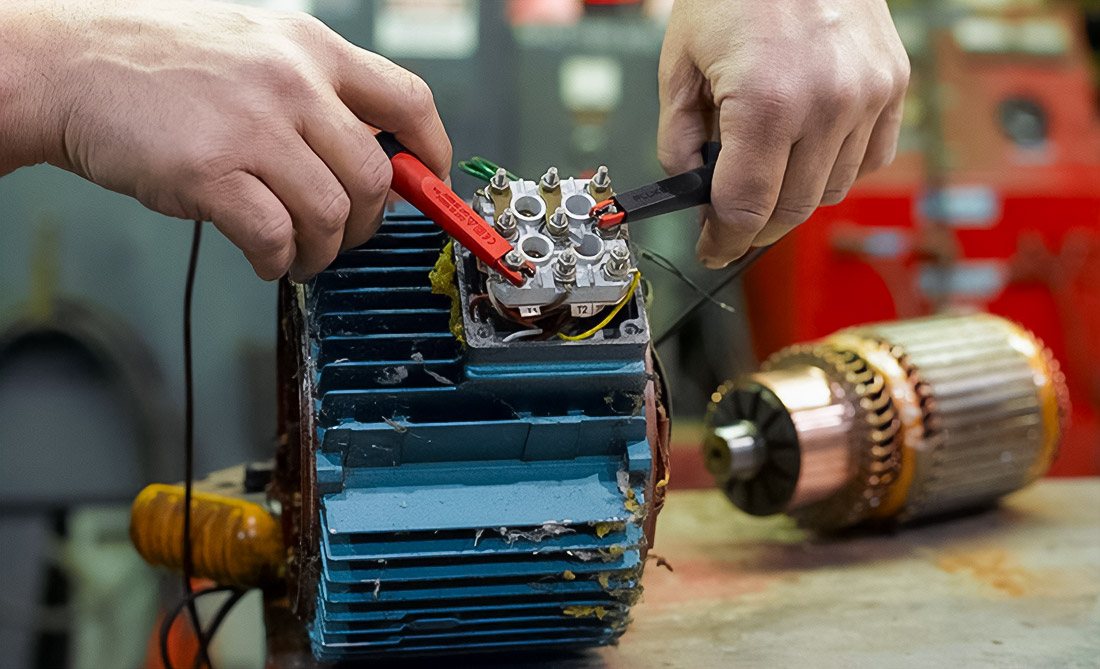

The brush may be new, the charcoal is clean, and the holder is in good condition, but a different contact is created under load. The switchboard appears smooth, but microscopic irregularities or an incorrect grinding angle become critical. The spark does not appear immediately, but increases with increasing current. As a result, the motor, which seemed to be working properly when opened twice, is still unstable.

Procedures and Measurements

Practice tells us that polishing alone is not enough. It is necessary to perform trimming, control the depth and shape of the grooves, observe the angles and processing speed. Even the choice of instrument plays a role. The technical materials contain control figures: 1, 2, 3 diagnostic steps; isolation in 2000 Mohm; reference books on 40 pages. This data is not a formality, but a database, without which it is easy to miss a little thing. And then the motor will give heavy sparking again.

Reliability Factors

Why is the topic so important? Because the engine does not work in theory, but in real conditions. Under load, friction increases, current increases, and sparking becomes severe. Keywords are often repeated in discussions: load, heavy, condition, motor, problem. They reflect the essence of the experience: motors require fine tuning, otherwise no checks will save them from failures. Even with round-the-clock operation – 365 days a year minor flaws quickly turn into serious problems.

Rebar turning and trimming is not a simple mechanical treatment, but a chain of actions where everything is important: from the number 2000 to the grinding angle. The experience of specialists, accumulated back in 2006 and supplemented by modern instructions for 2024 and 2025, shows that smooth operation under load can only be achieved by combining facts, measurements and discipline. The engine will then run not only at idle, but also withstand a real load without heavy sparking. In such processes, the involvement of an electro mechanical company is often critical, since they provide specialized expertise, precision instruments, and maintenance practices that directly influence long-term reliability.

Hello! My name is James Carter, and I am a passionate photographer from England. From the moment I first took a camera in my hands, photography became for me not just a profession, but a way to see the world. From spontaneous street shots to breathtaking landscapes – I dedicate my life to capturing the beauty surrounding us.